Everyone will be curious about the unique lithium-ion battery manufacturing process. The latest power source that has been used currently for providing power to vehicles is lithium-ion batteries. They are more energy-efficient, long life cycle, and have high power intensity; they are a better option as compared to other batteries.

Lithium-ion batteries have electrolytes at their core. Within five years, the demand for these batteries has risen by 70-90%. They are replacing heavy batteries in electric vehicles. In 2020, the market size of lithium-ion batteries was USD 36.90 billion. Hence, in 2021, the market grew by USD 44.49 billion, and according to a forecast, the market will grow by USD 193.13 billion by 2028.

Keep reading this article to know more about these advanced batteries and their manufacturing process.

1. What Is The Process Of Manufacturing Lithium-Ion Batteries?

The manufacturing process of lithium-ion batteries consists of electrode building, cell assembly, and then finish. Each stage of manufacturing these batteries involves multiple processes. Let us discuss all this in detail below!

1.1 The Manufacturing Process Of A Lithium Battery Is Higher Than Any Others:

Here are the three manufacturing steps of lithium-ion batteries in a little detail:

1.1.1 Electrode Manufacturing

The first step in manufacturing a lithium-ion battery would be to mix the electrode materials with the help of a conductive binder. However, the anode material that is used in the manufacturing process would be a form of carbon, and the cathode would be lithium metal oxide. These two materials don’t get mixed and would be processed in different rooms.

The slurry formed by mixing electrode material will then be coated on both sides of the current collector. An application tool is used, such as a doctor blade, slot die, and anilox roller. Nevertheless, the coating machine will control the electrode coating process, so the thickness wouldn’t exceed the limit.

· Calendering

To evaporate the extra solvent, the foil would go directly into the long dryer. After drying the solvent, the next step is a calendering process. A rotating pair of rollers would now compress the coated foils. This step helps in giving more shape to the physical properties of the electrodes.

· Slitting

Once the calendering process is completed, the electrodes would go into the slitting machine so that they will be cut down into narrow slides. Then, the narrow slides will get recoiled. To remove the extra solvent and residual, the coils go to the oven.

· Equipment Used In The Manufacturing Of Electrodes

- Vacuum mixers

- Coating machine

- Dryer

- Slitting machine

- Vacuum oven

1.1.2 Cell Assembly

After manufacturing of electrodes, the next step would be the cell assembly, which will be sent to the dry room for assembling. To make the internal structure of the anode and cathode cell, a separator will be layered between them.

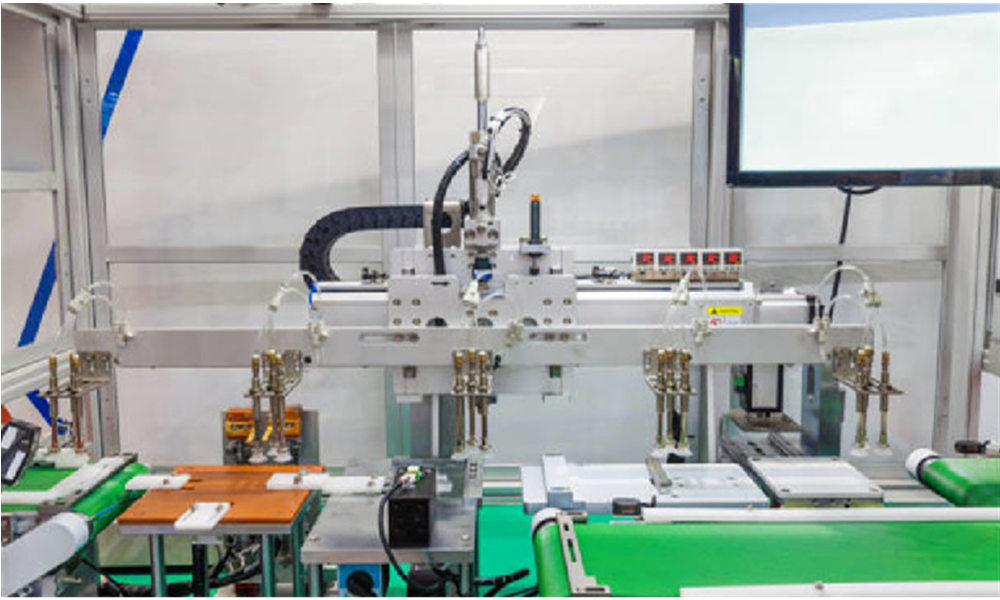

There will be two electrode structures that would be used depending on the size of the cell case. If the cells are prismatic and cylindrical, winding would be done for them. If the cells are pouch-shaped, stacking will be done. Through highly automated equipment, the cell assembly process gets completed.

- Laser Welding Process

The next step would be laser welding using ultrasonic. The cell structure would go into the terminal or cell tabs where this laser welding process will be carried out. The sub-assembled cells in cell housing will get sealed by laser welding or a heating process. But, it will leave an opening for the injection of electrolytes.

- Electrolyte Filling

Once the cells are sealed in the cell housing, it is time for filling electrolytes inside it. As you know the moisture in the air will decompose electrolytes while emitting toxic gases, this process will get done in a dry room. The electrolyte will get filled inside the cell housing using a highly precise dosing needle. After filling the electrolyte, the cell batch will get a serial or batch number.

- Equipment Used In The Process Of Cell Assembling

- Stacking machine

- Winding machine

- Vacuum sealer

- Cell packaging

- Tab welding machine

- Electrolyte filling machine

- Cell assembly line

1.1.3 Finishing

The last process of manufacturing a lithium-ion battery is the cell finishing process. After injecting the electrolyte into the battery, it will get charged. Yes, it will come to the first charge and then discharging the battery cells to check whether the manufacturing process has been done perfectly or not. From the anode side, the lithium ions are embedded into graphite crystals to form a safety layer on them. The safety layer is called a Solid Electrolyte Interface.

- Aging

After the formation of the safety layer on the anode side, aging gets started and the battery will go through quality check processes. The cell performance will get monitored regularly by measuring the OCV for up to three weeks. However, the distinction will get measured between normal and high-temperature aging.

- Testing

Once the aging process is completed, the last step would be testing the cells in an end-of-line. The battery will be taken to the testing station to check the charging and discharging time.

Equipment Used In The Process Of Cell Finishing

- Formation equipment

- Aging cabinet

- EOL testing machine

2. Practical Applications Of Lithium-Ion Batteries:

For most portable electronic vehicles, lithium-ion batteries get installed in them. The trend of electric vehicles is growing for aerospace and military applications. These batteries are also used in medical equipment and electric tools. Some smartphones, tablets, laptops, strobe heads, and cameras also have lithium-ion batteries in them.

3. Difference Between Lithium And Lithium-Ion Batteries

The most significant difference between lithium and lithium-ion batteries is the cell type that has been used in manufacturing them. The lithium batteries have primary cell construction, which means they are rechargeable and single. On the other hand, lithium-ion batteries have secondary cell production.

4. Conclusive Remarks:

In the end, we can say that the trend of using lithium-ion batteries is growing day by day. As the size of its market is increasing, we have mentioned that the USD market of lithium-ion batteries is growing. No wonder one day, these batteries will replace other types of batteries. We have discussed the whole process of manufacturing lithium-ion batteries. Thus, we hope that you are now able to know how these batteries work.