“Lithium battery” is a type of battery that uses lithium metal or lithium alloy as the negative electrode material and uses a non-aqueous electrolyte solution. Due to the very active chemical properties of lithium metal, the processing, storage and use of lithium metal have very high environmental requirements.

Lithium batteries can be roughly divided into two categories: lithium metal batteries and lithium ion batteries. Lithium-ion batteries do not contain lithium in the metallic state and are rechargeable.

The well-known Tesla electric car uses a battery panel composed of 18650 lithium-ion batteries in series and parallel. With the increasing popularity of new energy vehicles, the power battery industry has also become hot!

Below we will learn to understand the manufacturing process of lithium batteries in the form of diagrams.

The following will explain the 21 production processes of lithium batteries with pictures and texts:

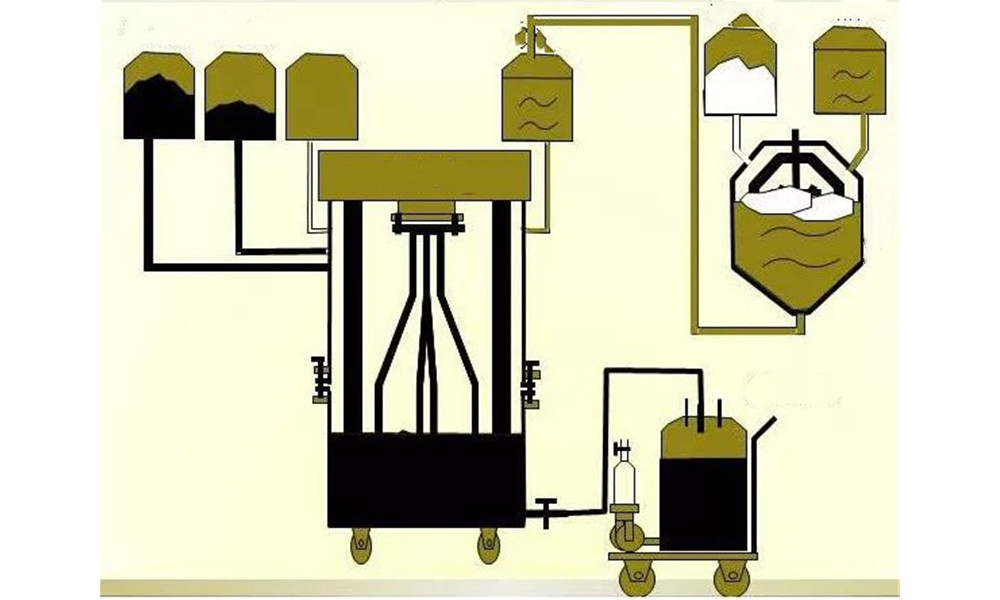

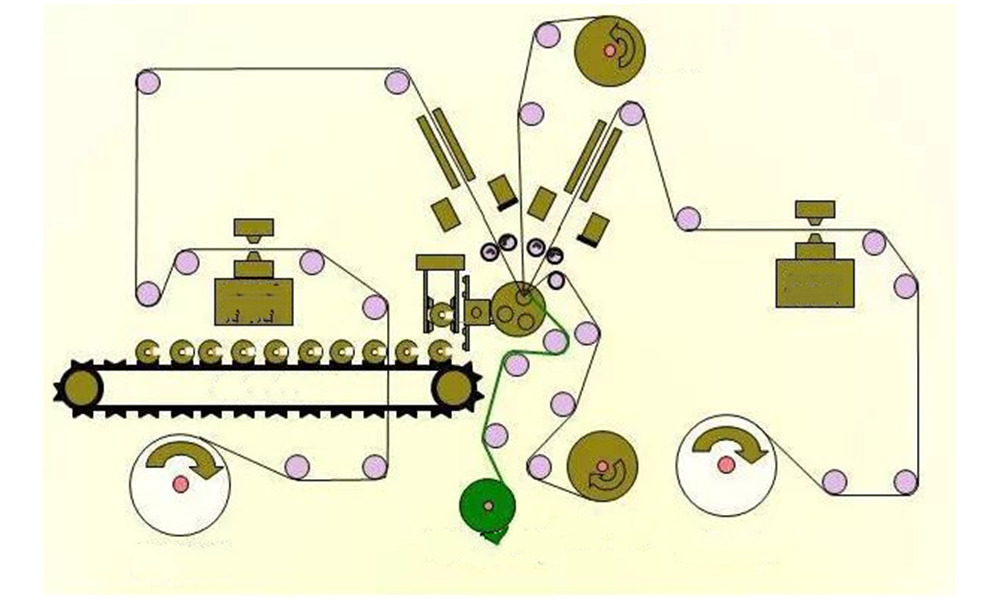

The first step is Negative homogenization:

The second step positive homogenization:

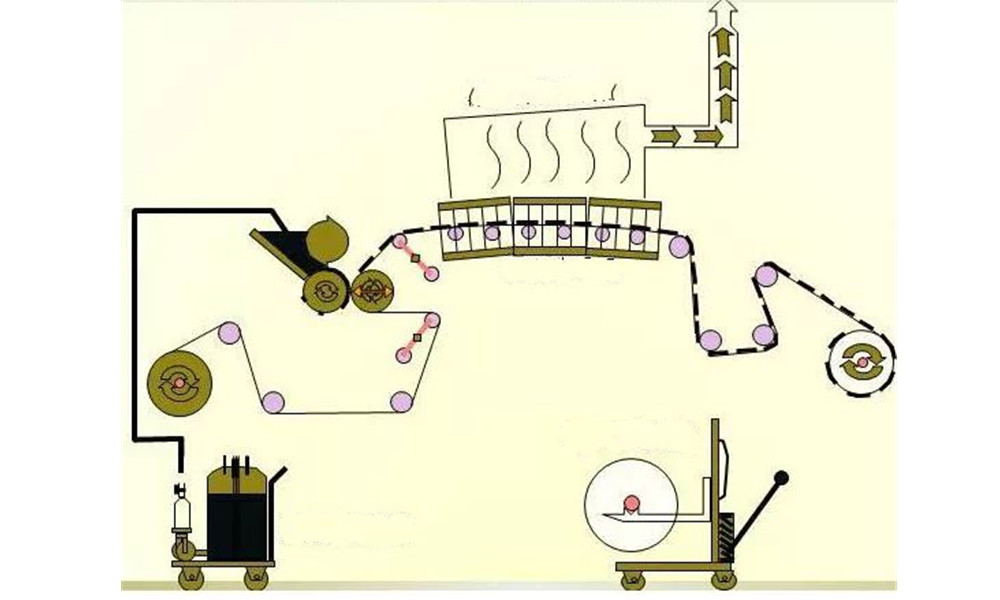

The third step coating:

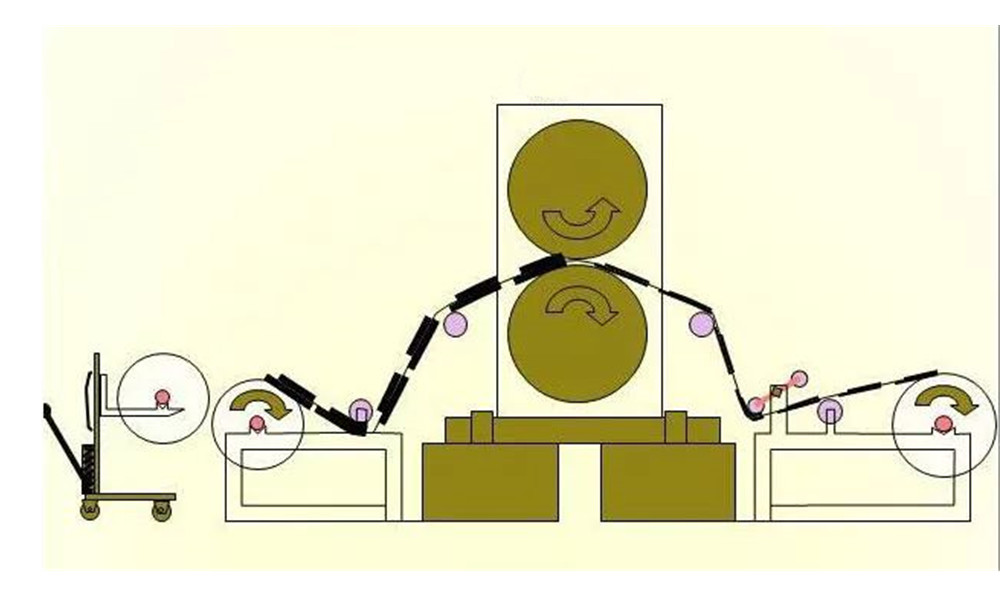

The fourth step is rolling:

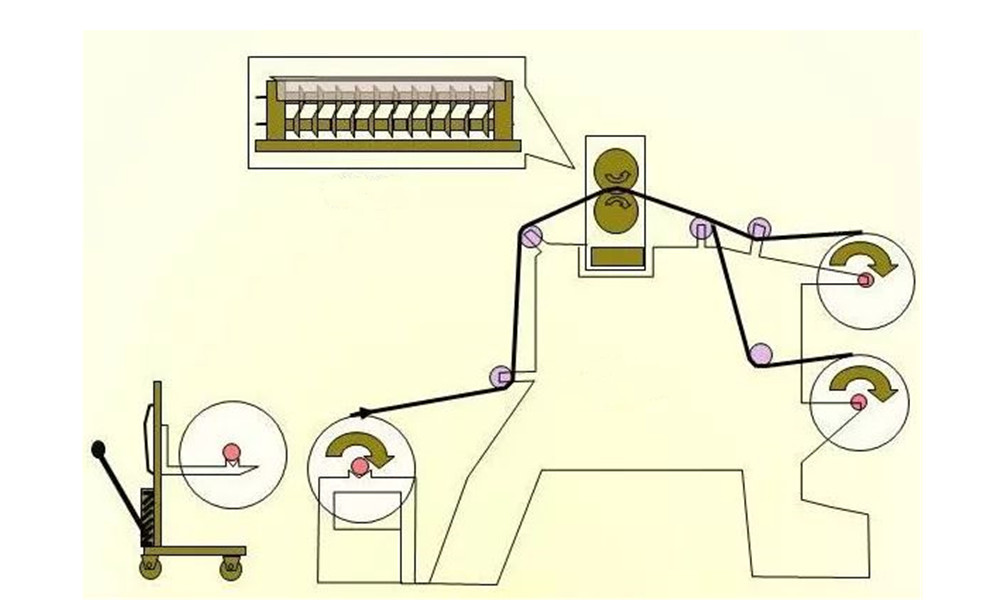

Step 5 Slitting:

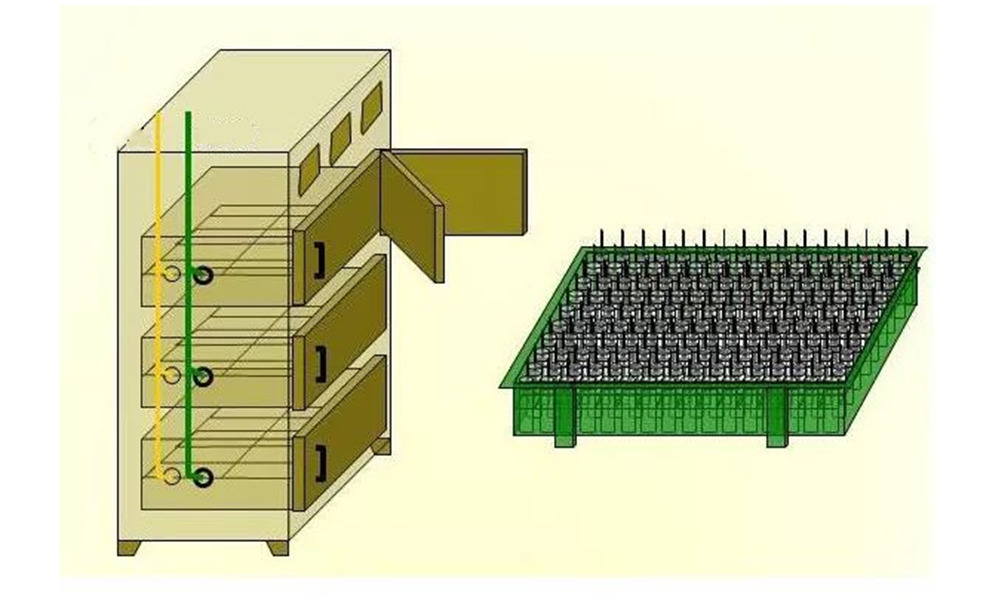

Step 6 Baking:

Step 7 Winding:

The eighth step into the shell:

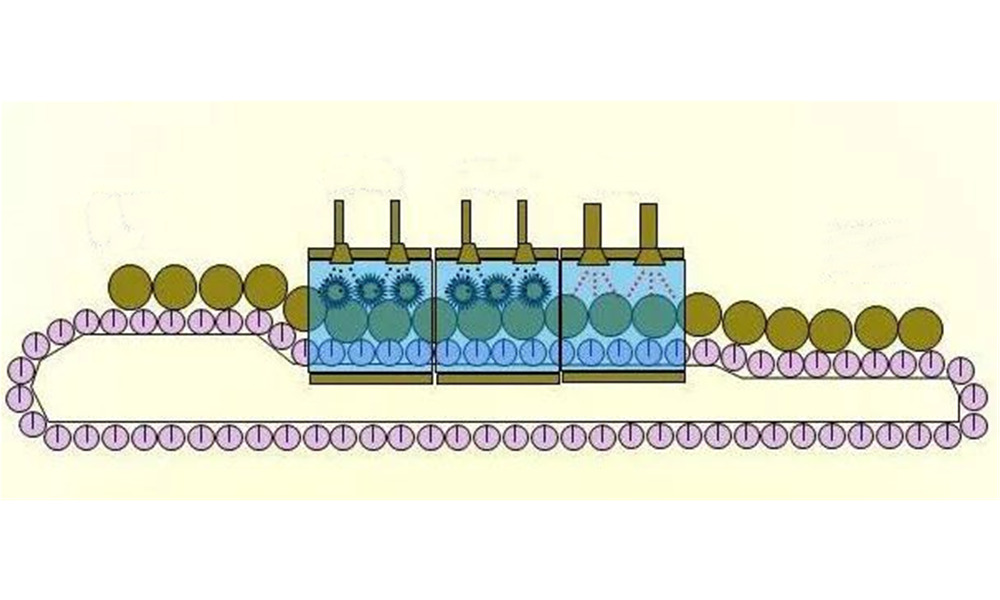

Step 9 Spot Welding:

Step 10 Bake:

Step 11 Injection:

Step 12 Weld the cap:

Step 13 Cleaning:

Step 14 Dry storage:

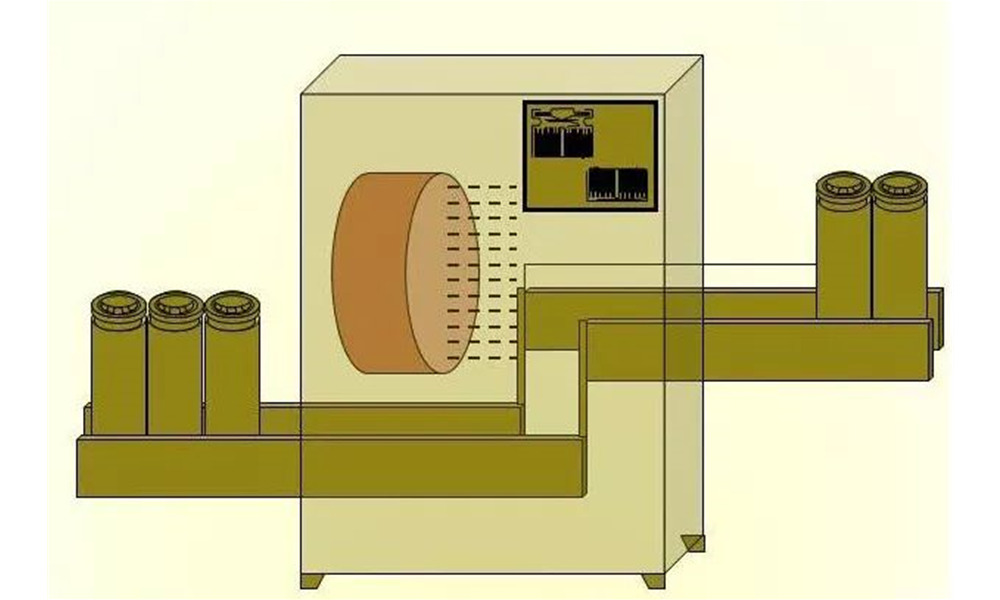

Step 15 Check Alignment:

Step 16 Shell coding:

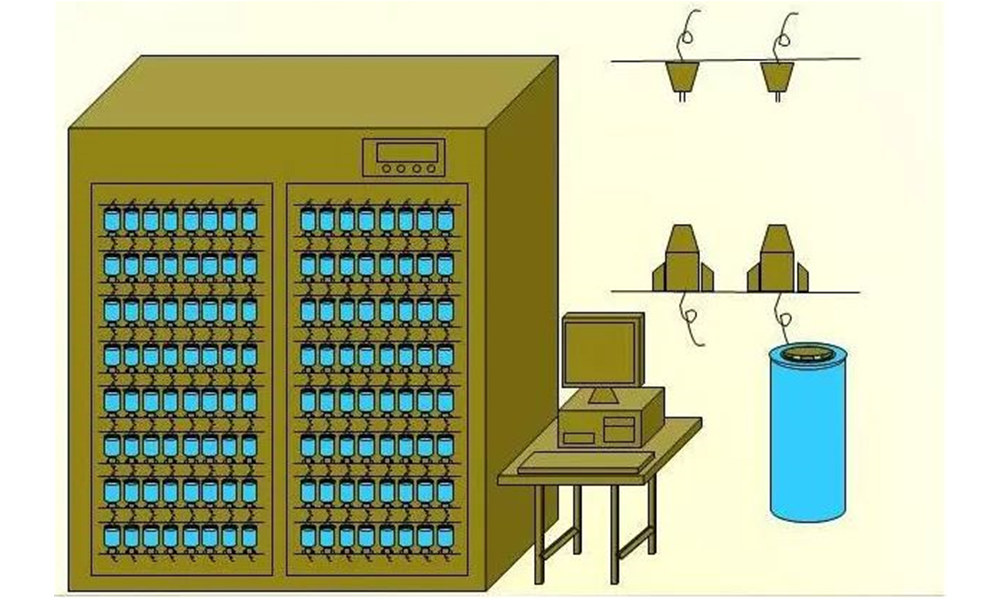

Step 17 Formation:

Step 18 OCV Measurement:

Step 19 Store at normal temperature:

Step 20 divide capacity:

Step 21 last final process:

How about it? Is this process complicated?