When lithium batteries became a common choice for mobile phone batteries, many people were worried that lithium batteries would have a memory effect like nickel-cadmium batteries. If they were not fully charged, they would leave traces in the battery, resulting in reduced battery capacity. It was not until later that it became popular science that it was more appropriate to keep the lithium battery power at 20%-90%.

Although lithium batteries are not bound by the “memory effect”, when many battery packs are put together, there is also capacity trouble. This trouble comes from the “short board effect”.

In the latest issue of the black technology video column “Bits and Watts”, Dr. She Hongwu, Huawei’s senior expert in digital energy, will focus on what is the shortcomings of energy storage batteries? At the same time, Huawei Digital Energy’s solutions to address shortcomings will be shared. It is this solution that perfectly supports the stable power supply of Huawei’s 1.3GWh microgrid energy storage system in Saudi Arabia’s “Red Sea New City”, allowing the world’s largest microgrid energy storage project to provide continuous power supply to an entire city with a population of nearly one million. of electrical energy.

1. The shortcoming effect comes from the inconsistency of the battery

What is commonly known as the “short board effect” is also the “barrel effect”: a barrel hooped by wooden boards. When the lengths of the wooden boards are inconsistent, it is obvious that the length of the shortest board determines the capacity of the barrel. Energy storage power stations also have similar problems.

An energy storage power station is composed of hundreds or thousands of single cells. These cells are arranged in integrated modules and connected to form battery clusters. Multiple battery clusters and converters and other equipment form battery compartments, which is what we often see. The “big cabinet”.

Is it true that as long as there are more energy storage batteries, the scale and actual capacity of the energy storage power station will be larger? The answer is, not necessarily. Precisely because there are many batteries, the probability of battery capacity reduction due to various reasons will also increase, and at the same time, the capacity of the energy storage power station will decrease.

One of the causes of capacity fading is caused by the inconsistency of individual cells. She Hongwu said: “Lithium-ion batteries are connected in series and parallel to form battery packs, battery clusters and energy storage systems. However, the inconsistency of lithium-ion batteries can easily cause series-parallel mismatch, which will affect the available capacity of the energy storage system.”

Even if the battery has very good consistency when leaving the factory, it is difficult for the battery to maintain a high degree of consistency due to different specific environments in the operation and application of the energy storage system. Among them, “temperature” is an important factor. Energy storage batteries are particularly sensitive to temperature. Although various energy storage systems are equipped with thermal management and control links, if not properly managed, it will lead to inconsistent attenuation of each battery. The series-parallel mismatch caused by this inconsistency may cause the system to Capacity therefore decreases exponentially. The larger the power station, the greater the probability of series-parallel mismatch, which will affect battery life and the total capacity of the power station.

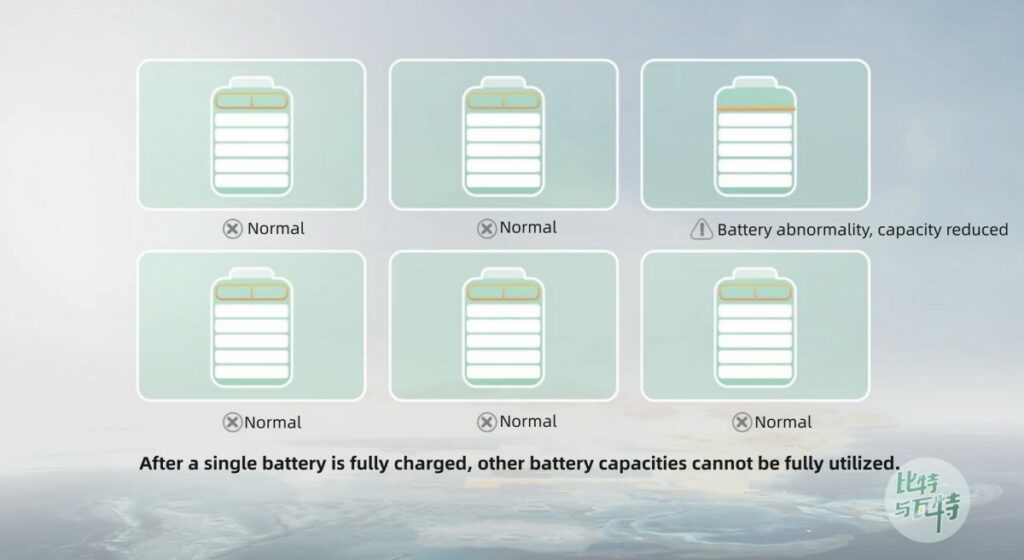

In addition to the series-parallel mismatch caused by battery inconsistency, the capacity of traditional energy storage power stations is attenuated, and there is another technical feature that is rooted in traditional centralized technology – the “centralized working” mode. When battery packs are simply connected in series to form a battery cluster, the currents are forced to be equal. When any battery pack is full or discharged, the entire battery cluster will stop charging or discharging. This is the impact of battery series mismatch. In the same way, when multiple battery clusters are simply connected in parallel, the voltages of each battery cluster are forced to be equalized. When charging, as long as one battery cluster is full, all battery clusters connected in parallel will stop charging. When discharging, as long as one battery cell has been discharged, the other battery clusters connected in parallel will stop discharging.

She Hongwu said: “This will cause the available capacity of the entire energy storage system to be determined by the battery pack with the smallest capacity.” This creates a short board effect: the capacity of the system depends on the stacking of batteries with smaller capacity, and the overall life span also depends on Battery with the shortest life.

The capacity mismatch problem caused by series-parallel mismatch is very serious. Some energy storage systems that have been put into operation have lost more than 15% of their capacity in the first year, and the actual discharge capacity is far lower than the standard capacity.

2.Huawei’s black technology: making the 1.3GWh energy storage system in Red Sea New City more efficient

How many batteries are there in the 1.3GWh energy storage system of Red Sea New City? International Energy Network consulted information and learned that the Red Sea New City energy storage system uses Huawei’s intelligent string energy storage solution. This solution uses a 20-foot standard container with a rated capacity of 2,064 kilowatt hours. The 2,064 kilowatt hours are divided into six battery clusters. , each battery cluster is further divided into 21 battery packs. Based on this calculation, the energy storage system of Red Sea New City has nearly 80,000 batteries.

To simultaneously control nearly 80,000 batteries to fully function, fully utilize cell performance, and ensure system safety, this requires Huawei’s unique black technology.

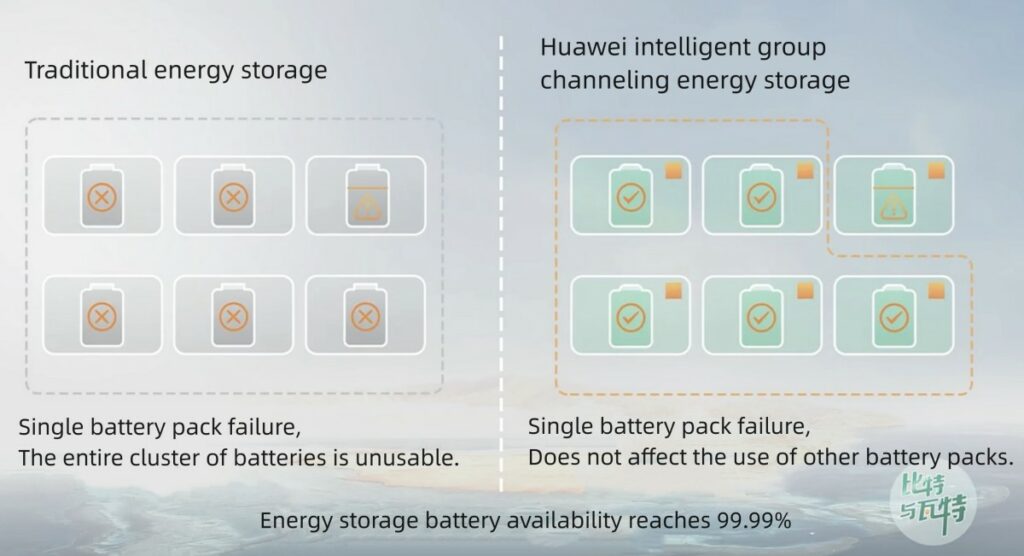

Huawei’s smart string energy storage solution first starts with the structure and proposes a different approach from traditional solutions: using a modular design, if a single battery pack fails, it will not affect the use of other battery packs; if a single battery cluster fails, It does not affect the use of other battery clusters. These measures enable energy storage battery availability to reach 99.99%.

Secondly, we start from the perspective of technological innovation and rely on two black technologies to solve the shortcomings of energy storage batteries. These two black technologies, one is Huawei’s unique algorithm, and the other is Huawei’s specially developed battery cluster controller and battery pack optimizer.

Through “algorithm” visual monitoring of battery packs, abnormal batteries can be accurately captured.

The working principle of the battery pack optimizer is to isolate it individually after detecting fault abnormalities. In this way, after a single battery pack is fully charged or discharged, it will not affect the continued charging and discharging of other battery packs. She Hongwu said: “Huawei uses the battery pack optimizer to manage battery module groups and reduce the impact of battery series mismatch.”

Each cluster has a controller and each package has an optimizer. This is the technical foundation for the stable power supply of the 1.3GWh energy storage system in Red Sea New City. Practice has proven that this power supply method can not only ensure stable power supply, but also effectively increase the charge and discharge capacity by 6%.

On this basis, each battery cluster is connected to the intelligent battery cluster controller. The battery management system can independently adjust the working voltage of each battery cluster through the intelligent controller to keep the charging and discharging current consistent and fundamentally avoid bias current. of production. Through separate management, the charge and discharge capacity can be increased by another 7 percentage points.

To address the “heat dissipation” issue that has a great impact on energy storage systems, Huawei adopts a distributed heat dissipation architecture. Each battery cluster is independently configured with an industrial air conditioner, which can effectively avoid differences in container cooling effects and try to avoid consistency differences due to temperature, thus laying a foundation for reducing series-parallel mismatch.

To sum up, the characteristics of Huawei’s technology are “one package, one optimization, one cluster, one management, and distributed heat dissipation.” According to Huawei’s actual measurement statistics, when using the intelligent string energy storage solution, if a single battery pack has a problem, the impact will be only about 16 kilowatt hours, and other battery packs will not be affected at all. Superimposing intelligent internal short-circuit detection to achieve passive safety to active safety, the cost of energy storage systems will be reduced by about 10%.

With the algorithm and the battery pack optimizer in hand, no matter how well the faulty battery is hidden, there is nowhere to hide it. More importantly, this decentralized and modular solution is equivalent to breaking down the “big bucket” into independent “small buckets”, and then making up for the shortcomings in each “bucket” to maximize the optimization of the entire system. It not only solves the shortcomings The plate effect also provides guarantee for the capacity and life of the energy storage system.

It is on the basis of solving the battery problem that the giant power bank, the 1.3GWh energy storage system built by Huawei for Red Sea New City, can provide stable power supply to the residents of Red Sea New City on the coast of the Red Sea.