During charge and discharge, the cell’s thickness change leads to pressure variation and directly influences the performance of electrochemical properties, safety, and reliability of cell, module, and battery.

In order to study the change and correlation clearly, the modeling and simulation for the actual work structure and status of batteries (in-situ thickness, in-situ pressure characteristic parameter) are very important. as shown in the following diagram.

Irreversible loss and degradation lead to electrode /Cell gradually thickness increase, ALP, etc. Ex-situ and destructive traditional methods can’t meet current requirements due to their high cost, and low efficiency, only one sample can be tested in one experiment.

- Realize Multichannel in-situ pressure and thickness test for Coin, single stack, pouch, and prismatic cell;

- help for materials development, structural design, process optimization, and related mechanism research;

- Provide reliable mechanical parameters for the module, and pack design.

1. Brief introduction of multi-channel in-situ expansion force testing system

Through intensive integration of high-precision die frame, displacement, voltage, current, pressure, temperature and humidity, and other core components and sensors, the test system can accurately test the In-situ thickness and swelling pressure of multiple cells at one time.

1.1 Main function:

- Multichannel In-situ Swelling Analysis System;

- AIO, one-stop solution;

- For coin, single stack, pouch, and prismatic cell;

- High precision thickness measurement, the resolution is 0.1μm and accuracy is ±1μm;

- High precision continuous dynamic pressure guarantee, maximum accuracy is ±10N;

- Synchronous monitoring and collection of Electrochemical parameters, pressure, thickness, temperature, humidity, and so on.

- Environmental simulation at different test temperatures (- 40 ℃~100 ℃);

2. Application

2.1 In-situ expansion force analysis of multi-channel cells

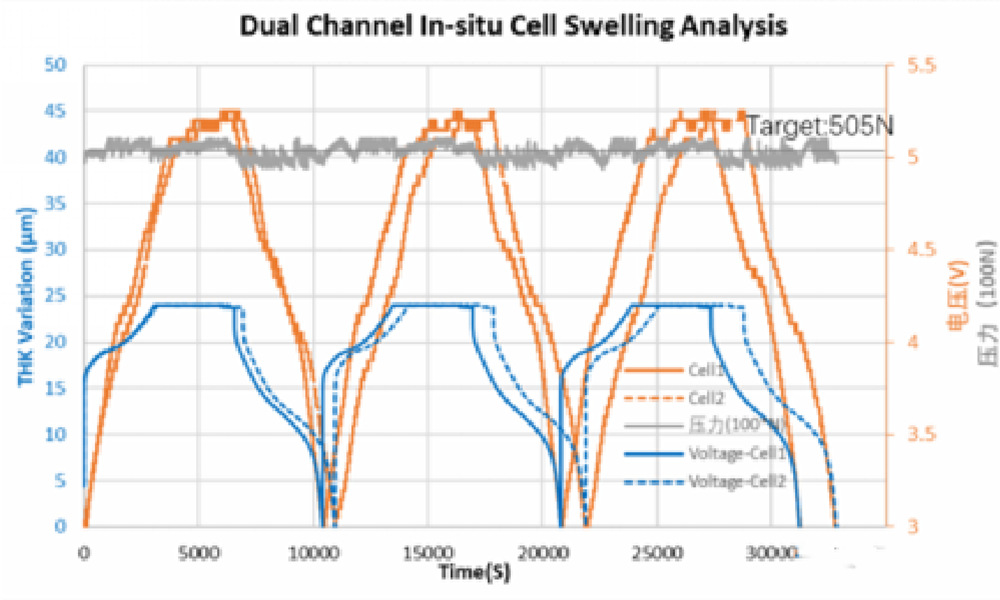

In the dual-channel in-situ expansion test mode, the cell sample is guaranteed to be tested at exactly the same pressure; With the charging of the cell, the absolute thickness and relative thickness of the cell are detected synchronously;

Two cells based on the same design exhibit the same level of swelling (thickness changes consistently), but the polarization of cell 2 is relatively larger;

2.2 Analysis of cell expansion performance under different constant voltages

In constant pressure mode, the cell swelling pressure is unchanged during charge-discharge. The absolute thickness of the cell decreases with the increase of loading pressure. With the decrease of charging current (CC+CV stage), the increase rate of cell expansion thickness gradually decreases.

2.3 Analysis of cell expansion performance under different constant voltages

ALP(Anode Lithium Plating) is the most safety issue, so the analysis and prediction of ALP are very important. Based on the in-situ swelling pressure testing system,) ALP can be predicted.

3. Summary

In this paper, the multi-channel in-situ swelling test system (CSA1150) is used to test the swelling of cells, which solves the problem that the existing measurement method can only one parallel sample be tested at a time, and fully ensures the consistency of the pressure control of the test, which is helpful to evaluate the material modification and the process formulation development more accurately and quickly.